Central Coast 3D Printing prints parts utilising a variety of technologies to meet your needs. We maintain both Fused Deposition Modeling (FDM) and Digital Light Projection (DLP) 3D printers in house, and we stock a wide variety of materials.

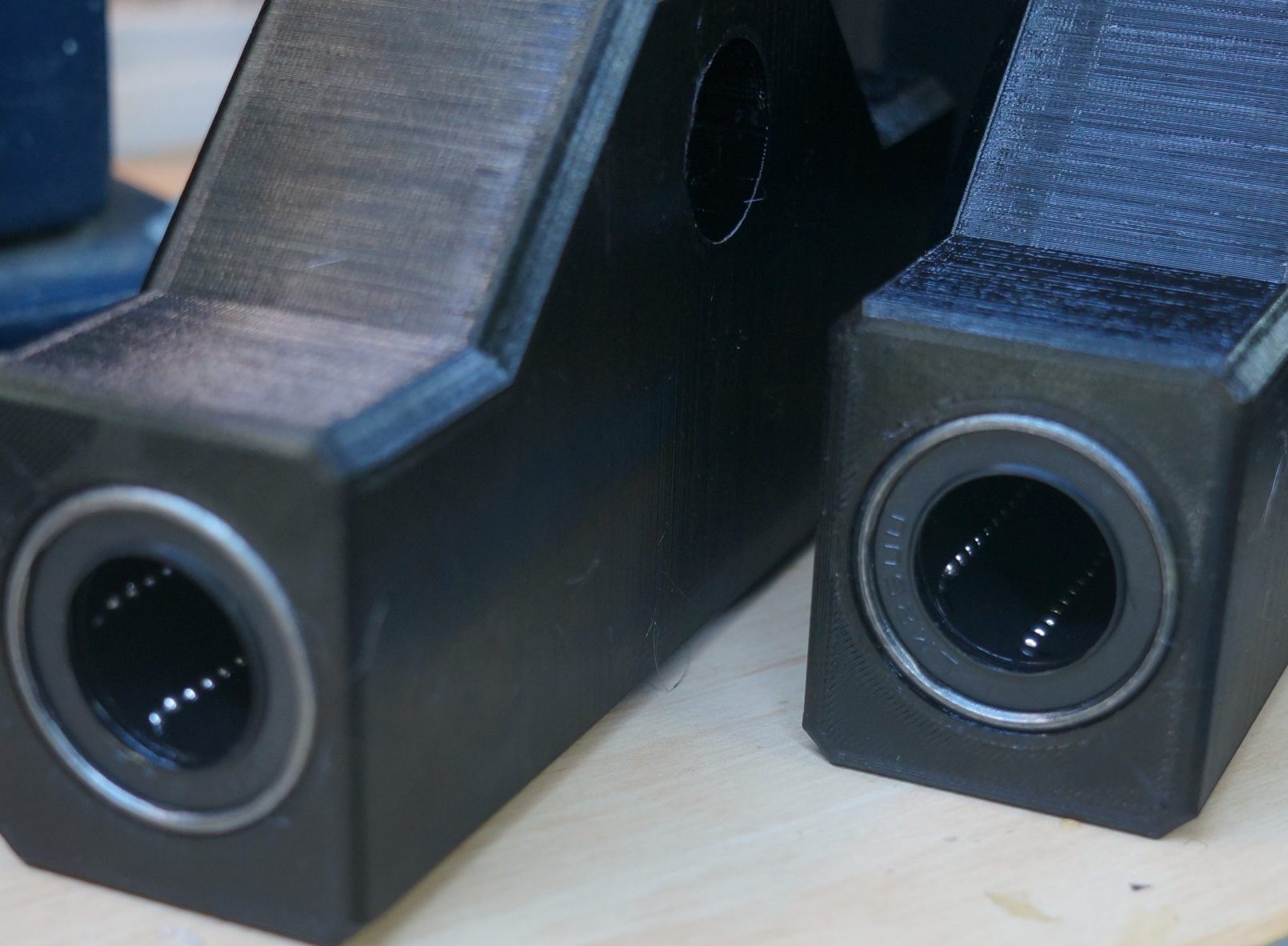

FDM 3D printers create objects using the “traditional” printing method of heating thermoplastic filament and extruding it in layers on a heated glass bed. FDM is extremely flexible in terms of resolution and the types of materials that can be used. FDM is great for quickly and cheaply producing parts to determine qualities like aesthetic design, ergonomic shape, and for small batches to perform product testing.

DLP 3D printers create objects using an LCD screen and UV light to solidify light sensitive liquid resin in a series of layers. DLP offers extremely high resolution (great for branding and mold making) and offers high performance materials for unique jobs. We maintain a steady stock of standard, flexible, and rigid resin for our customers.